Concrete block making machines are mainly used for making concrete building blocks which are used in construction for building of walls. Concrete building blocks are also commonly called a concrete masonry units (CMU). A CMU is one of several dry cast concrete products that can be made on a concrete block making machines.

With a simple mold change, concrete block making machines can manufacture many different shapes, sizes, textures and colors of concrete products depending on the customers’ requirements.

Concrete block making machines are available in output capacities from 1000 to 25,000 (8”x8”x16”/ 10x10x20cm) building blocks per 8-hour shift.

The advantages of owning versatile concrete block making machines includes high output production with the ability to manufacture a wide variety of products that can be produced by using only one block block machine. The products machine incorporates a vibratory system that uses a dry cast concrete mix to fill the empty mold cavities with concrete mix. Once the mold cavities are full of concrete mix the same vibration system is also used during the compaction stage of the process for making concrete products. This complete process is very fast and requires very little cement content in the concrete mix compared to a wet cast or ready concrete mix.

Our simple concrete block making machine system can make 2200- (8”x8”x16” / 20x20x40cm building blocks per day.

Our advanced building block building block and paving stone machines are capable of manufacturing a wide variety of concrete products. I’ve listed below, a few of the hundreds of products that have been produced on our equipment.

| Concrete Hollow core building blocks | Rubber blocks | Solid Building blocks | Split blocks |

| Interlocking street pavers | Kerb stones | Concrete Erosion Control blocks | Fencing blocks |

| Solid and cored bricks | Lawn edger’s | Manhole adjusting Rings | Silo blocks |

| Insolated building blocks | Rebar Spacer blocks | Mortarless building blocks | Drainage blocks |

| Retaining Wall blocks | Landscape units | Architectural Cast Stone Products | Water meter boxes |

| Thin set pavers ¾” (19mm) thickness | Cribbing | Mining support Blocks | Roof Ballast slabs |

| Roof shingles | Air conditioner pads | Rubber pavers | 100% Fly Ash Pavers |

| Soffit Cored Blocks | Screen Block | Electrical meter box | Parking Bumpers |

| Manhole Blocks | Splash Blocks | Deck Blocks | Dobie spacers |

Versatile concrete block making machines can make hundreds of different shape & sizes of concrete products with a simple mold change.

Wood Structured Block (made of all of wood chips)

Steel Slag Pucks (Formed into small oval shape. Cured pucks are sent back to the steel mill furnace for recycling)

Washing machine Counter weights (Used in washing machines)

Roof ballast Slabs (to support and protect rubber membrane roofing)

Mine Support Crib Supports (Has steel in block 1/64” flatness Spec)

Rebar Dobie Spacers (supports flatwork rebar during construction)

Rubber Mats (used for flooring as construction material)

Fire insert blocks (used in fireplaces)

Red clay pavers (ground to showing natural beauty of clay chips)

Exposed aggregate slabs made from seashells and also granite.

Silo blocks (used to make grain silos)

Slabs 24”x24”x1/2” (609x609x12.7 mm) then grinded and polished

I get many requests each day for machinery and many people start the conversation by asking me the same question, “I need a cheap concrete block making machine, something to just get started for $8000.00 or less. What is the price of your concrete block making machine?”

Although I know price is always important to any investment many people often believe a cheap block machine is all they need and they will be successful. Unfortunately purchasing industrial machinery is not as simple as buying on just price. If you are trying to buy on just price it is a very risky game. It would be similar to walking into the hospital and asking the heart surgeon what is the cheapest heart surgery you have? The first question the doctor should have for you is tell me more about why you think you need to see me for heart surgery? What type of surgery do you need and why? The doctor’s job is to provide the best solutions for you and not be selling you a cheap alternative that will not accomplish what you need or want.

It sounds so simple but unfortunately I have seen too many newcomers to the industry purchase equipment on price alone and throw their money away because they did not choose the correct concrete block or brick machines and equipment or understand it is a system they are buying, not just one machine.

I would really enjoy for us to do business together so please take my sincere suggestions and do just a little research and ask a few simple questions to suppliers you research. Explore all the options and when you are done looking and doing your research I would enjoy talking with you.

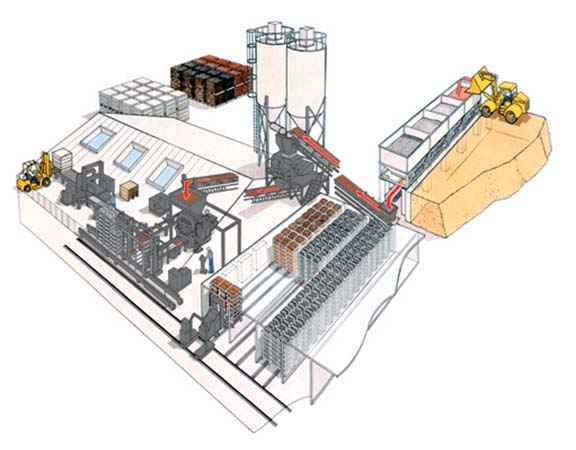

The question you should be asking yourself and suppliers is in my opinion, what does it cost to get started in the block making industry with everything I need? The block machine itself is just one piece of many pieces of equipment you will need. Please don’t get fooled that all you need is a block machine. That is far from the truth.

Contact us for more information about concrete block machines.