Global Machine Market – The Best in Concrete Block Making Machines

If concrete block-making is an integral part of your business operations, Global Machine Market can provide the equipment you need to continue growing production rates efficiently. Global Machine Market has over eight decades of experience to its name and is proud to carry only the highest quality concrete block-making machines and systems available on the market.

We readily provide customers with reconditioned products at competitive prices upon request. However, those who are looking for a brand-new concrete block-making machine for sale in the USA will find that here, too!

Top-of-the-line concrete block machines are our specialty at Global Machine Market. To that end, customers who value efficiency, durability, and precision are sure to find everything they’re looking for within our Level 5 concrete block-making machine series.

Finding quality equipment shouldn’t be a guessing game. That’s what makes the Level 5 block building machines so exceptional.

Having the right equipment in place — especially when you’re in the process of growing a new business — is vital. Individuals and companies that are looking for a new concrete block-making machine to build a foundation of success from the ground up will find that the Level 5 series checks every box on the list.

Overall, the Level 5 series is popular for beginners who are searching for a new concrete block-making machine for sale that’s affordable, easy to use, and able to provide effective results. At Global Machine Market, we carry all three models within the Level 5 series. These options provide our customers with selections that can easily be tailored to their business needs, whether they’re looking to craft building blocks or interlocking street pavers.

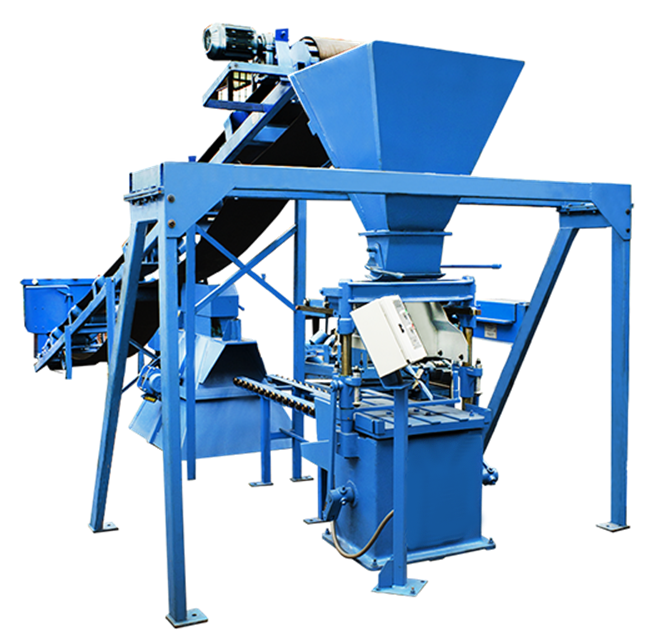

Customers who come to us looking for concrete block-making equipment will enjoy the selection of the GM63R-25, the GM63, and the GM3 models. Each model is designed with unique power and production specifications and can be paired with feeding mixers and conveyors, too.

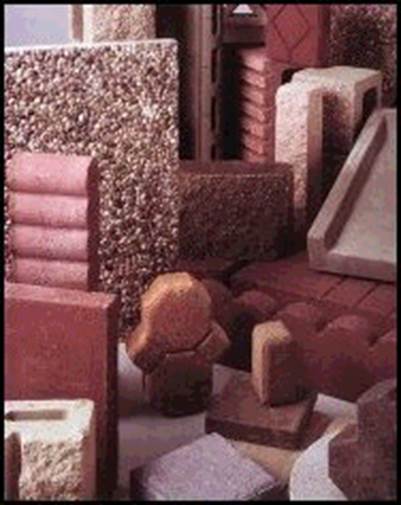

GM3 Building Block machine makes USA quality strength blocks & pavers.

The GM3 Concrete Block Building machine makes both building block & interlocking street pavers.

How a New Concrete Block-Making Machine Benefits a Business

The concrete block-making business has long been on the rise. Entrepreneurs and professionals who are working in a variety of fields and industries can benefit from the acquisition of a new concrete block-making machine that enhances production levels and opens up possibilities for expansion.

While concrete block making has significant potential for bringing profit, it’s also a process that provides smaller businesses with a high degree of production flexibility. Instead of waiting around for concrete suppliers who may or may not deliver concrete products on time, businesses can take matters into their own hands and create the products they need on a timeline that works for their business.

Many business owners begin the hunt for a new concrete block-making machine for sale when they realize that there is significant savings potential from installing their own production equipment, rather than buying materials from suppliers. Investing in a new concrete block-making machine that boasts the same features suppliers use allows businesses to customize production according to their needs and budget.

From producing hollow core building blocks and solid core building blocks to interlocking street pavers in all shapes and sizes, these machines allow for customized results at every turn. Those who are looking for a new concrete block-making machine for sale in the USA will find that investing in equipment like this provides options when it comes to setup. Level 5 series machines can easily be moved between job sites or set up in a permanent location.

The choices don’t end when business owners locate a new concrete block-making machine for sale. When you partner with the team at Global Machine Market, you can browse our extensive selection of add-ons.

Each of our high-quality machines comes with options to upgrade your production standards by adding features such as:

- Production pallets

- Concrete mixers

- Conveyors

- Rack storage

Concrete block-making machines play an important role in many types of projects. At Global Machine Market, we can cater to professional commercial businesses, as well as customers that are involved in nonprofits that have a focus on building and development. For these individuals, the purchase of a concrete block-making machine can elevate the services that they can provide to those who are in need.

Many of our customers see the endless financial opportunities that can arise from producing their own concrete blocks. For our customers who serve the construction industry, the opportunity to guarantee quality products of their own creation instead of depending on suppliers is an option that’s too beneficial to pass up.

Concrete Building blocks, Pavers & Bricks can all be made using a GM3.

Reasons to Partner with the Team at Global Machine Market

At Global Machine Market, we take an international approach to business and are proud to provide companies around the world with easy access to top-quality concrete block-making machines and systems that change the way they do business. We’ve centered our business on integrity and efficiency for over 80 years and continue to pass on that legacy to all of the customers that we serve.

As a family-owned business, we understand the importance of pairing impeccable customer service standards with quality products to match. To that end, all of our Level 1 machinery is made in North America. Our equipment produces concrete that exceeds national quality standards.

Our professional team is always available to help walk customers through our many machines and system configurations to make sure that they end up with the products that will best fit their business needs. We also offer professional installation and training on equipment that is purchased to guarantee that our customers will enjoy their investments for years to come.

From free consultations to transparent pricing, we work hard to make sure that purchasing a concrete block-making machine is as simple as possible. Our customer support representatives are bilingual in English and Spanish, making our services that much more comprehensive and inclusive for our many customers.

When you’re ready to take control of your business with the purchase of concrete block-making equipment, we’re here to help. Reach out to Global Machine Market today to learn more about our many concrete-making products and services.

What are the differences between the three Level 5 building block machines?

Within Level 5 stationary block machines we have several models to choice from starting with the largest level output level machine system. All the stationary building block machines have the options of operating of three phase electric motors, with generators or gasoline powered engines. All engineering drawings including electrical specifications are supplied at no charge. Electrical motors will be supplied to your countries Hertz, voltage requirements. Also we will supply you drawings for local fabrication of production if you desire to produce the pallets local instead purchase form us directly.

GM63R-25

This advanced machine is equipped with an electric vibration system and hydraulic power unit. The machine operator pushes a control switch releasing freshly made blocks from the production mold. A second control switch is pressed and the block product, which is made on a production pallet is pushed from molding area automatically. Production pallets are then taken to transport to curing area by many different methods. This machine has added capability to make concrete products up to 25cm (9” 7/8”) in product height. This machine will therefore make the Nigerian standard 9” block.

The GM63-R is a more automatic building block machine, requires less labor, has greater daily output production than the standard GM63.

PRODUCTION OUTPUT OF GM63-R

| Concrete Masonry Units Units per cycle |

CMU Size of Block |

CMU units in 8 hour shift |

| 2 | 9”x 9”x18” (22.8 x 22.8 x 46.6cm) | 2,200 |

| 2 | 8”x 8”x16” (20 x 20 x 40cm) | 2,200 |

| 3 | 6”x 8”x16” (15 x 20 x 40cm) | 3,300 |

| 4 | 5”x 8” x 16” (12.7 x20 x 40cm) | 4,300 |

| 5 | 4”x 8” x 16” (10 x 20 x 40cm) | 5,500 |

We like the concrete block making machine. We produce 12 hours a day, 5 days a week making high quality concrete products.

GM63 concrete Building Block machine, Conveyor & Mixer is ideal for making concrete building blocks & Pavers.

GM63

The next of the three Level 5 models available is the GM63. The basic machine is the same as GM63R but does not operate with a hydraulic operation and electric push button operation. The controls are operated semi manually with no hydraulics of electric used other than for the vibration system. The output of the machine is very good for a machine system and the machine has no hydraulic power unit and absolutely makes a USA quality block.

Please click on the below link and when it opens click on the forward arrow to see the simplistic GM63 block machine making concrete bricks. You will hear me guide you through the process of making concrete products from mixing raw concrete materials to the curing of the concrete products. Be sure to turn up your speakers.

PRODUCTION OUTPUT OF GM63

| Concrete Masonry Units Units per cycle |

CMU Size of Block |

CMU Production in 8 hour shift |

| N/A | 9”x 9”x18” (22.8 x 22.8 x 46.6cm) | N/A |

| 2 | 8”x 8”x16” (20 x 20 x 40cm) | 2,000 |

| 3 | 6”x 8”x16” (15 x 20 x 40cm) | 3,000 |

| 4 | 5”x 8” x 16” (12.7 x20 x 40cm) | 4,000 |

| 5 | 4”x 8” x 16” (10 x 20 x 40cm) | 5,000 |

GM 3

One of the most popular model level 1 stationary machines sold is the GM3 because of the small simple design and being versatile as a permanent or portable building block machine block plant. The output capacity and ease of moving the machinery directly onto the job site makes it ideal for a startup operation. The return on investment in extremely fast and can be shown to you in Global’s Profit Program.

The machine is equipped with electric vibration motor and compaction head for the production of building blocks, pavers, and a wide variety of other concrete products with a simple five minute mold change.

The concrete building products are formed on either wooden or steel production pallets and then taken to an area for overnight curing of the products. Once cured approximately twelve hours the concrete products are taken off the productions pallets and the productions pallets are returned to the block machine for reuse for that day’s production. The concrete products are generally stacked on wooden shipping skids for truck transport and remain in the shipping yard for ten days to further cure fully cure gain further strength and eliminate shrinkage in the blocks. Removing the blocks from the production pallets onto shipping pallets and returning production pallets to the block machine normally uses six to eight people.

PRODUCTION OUTPUT OF GM3

| Concrete Masonry Units Units per cycle |

CMU Size of Block |

CMU Production in 8 hour shift |

| 1 | 8”x 8”x16” (20 x 20 x 40cm) | 1,000 |

| 1 | 6”x 8”x16” (15 x 20 x 40cm) | 1,000 |

| 1 | 5”x 8” x 16” (12.7 x20 x 40cm) | 1,000 |

| 2 | 4”x 8” x 16” (10 x 20 x 40cm) | 2,000 |

When you purchase equipment from Global Machine I personally become your consultant for one year to help ensure you get the operation up and running and discuss all aspects of the business to make your business successful. It is important to understand that a block machine is only machine in a series of machines required put together that make up a block plant. For people not in the industry I often explain the process of making concrete product made on a block machine to making cookies in a bakery. In a bakery you need to have very good ingredients and exact measures of those materials if you expect to make good cookies. Once the materials are correctly measured and placed into a blender or what we call a concrete mixer they are mixed to the proper consistency. It is vital as in making cookies to have the proper amount of water added the mix perfect for making good saleable products. It the concrete industry we transport the products on what we call product pallets and in the cooking business they call cookie sheets. Although we don’t bake concrete products the products are set in an area overnight that allows the cement in the block to start hydration. Ideally concrete products are away from any direct sunlight and wind which would retard the hydration process which leaves you with less than desired strength products. Once cured overnight or as in a bakery cooked for the proper amount of time the products are remove from the product pallets and stacked for further curing outside for several days. The production pallets are reused that same day to make concrete products and the process of using the pallets repeats itself.

With level 1 systems you have many options on how to prepare the materials prior to being put into the mixer from manually to less labor intensive methods which reduce labor. The same is true after the concrete products are made and taken away from the block making machine. This can be done simply manually or by the assistance of pull carts to roll groups of product pallets away to curing area for overnight curing.

Below are various options for all different Level 1 machine systems. I hope this will provide you an overview of the systems available.

#1 Manual Feeding Mixer & Block Machine

(Loading materials into mixer and transporting to block machine 1-4)

Mixer is loaded by manual labor using premeasured buckets of sand, rock and cement. This will ensure consistency and add the water into mixer by manually. Once materials are mixed the concrete is taken to the block machine by wheel barrel and then shovel feed into the block machine mold. As your business grows additional measuring hoppers and conveyors can be used to reduce labor and raise the consistency factor in regards to the mixer and batching operation.

Pan Concrete Mixer 500 Liter.

#2 Manual Feeding Mixer & Conveyor to Block Machine to GM63 Block Machine

Mixer is loaded by manual labor using premeasured buckets of sand, rock and cement. This will ensure consistency and add the water by hand. The mixed concrete is transported to the block machine by powered rubber belted conveyor which will distribute concrete into the block material hopper located above the machine. Using a conveyor with reduce labor and increase the output production of concrete products per hour.

Concrete pan mixer & belt conveyor to take mix to concrete block machine.

#3 Wheel Barrel Mixer Loading & Conveyor Feed to GM63 Block Machine

Concrete Mixer is manually loaded by using wheel barrel. This will ensure consistency and water is added to the mix manually. Once mixed the concrete is transported to the block machine by powered rubber belted conveyor which will distribute concrete into the block material hopper above the machine. Using a conveyor with reduce labor and increase the output production of concrete products per hour.

Wheel Barrow loading aggregates to concrete mixer to make building blocks and paving stones.

#4 Loader Fed to Mixer & Conveyor to Block Machine GM63R

Mixer is loaded by front end loader. This will reduced labor and measure ingredients by either weight or volume and then add the water by manually. The mixed concrete is taken to block machine by powered rubber belted conveyor which will distribute concrete into the block material hopper above the machine.

Loader picking up aggregates from storage piles then To Concrete aggregate bins and Pan Mixer.

GM63 Series Product Handling Equipment Options

(Handling freshly made units from the block machine to curing area 1-7 )

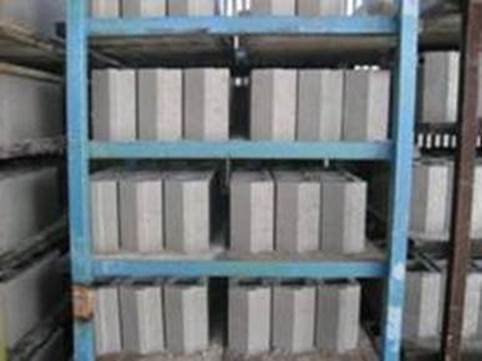

#1 Rack Storage

Production pallets from the block machine are placed into a steel production rack by hand or by air operated arm. Racks can be designed in many sizes and generally hold 36 production pallets and transported by fork lift to curing area. The first reason why a person would choose this option is the huge savings in space. The second is if they add a curing room steel racks don’t wear out. It also allows them to handle steel production pallets which also have a long life cycle and allow them to place the racks with blocks into an enclosed curing room atmosphere to gain better next morning’s strength.

Building Block Machine, steel production pallets & Radial Arm Off Loader.

Loaded Pallets of Building Blocks into Racks.

Concrete Building Blocks Curing in Production Racks.

Show a picture of plant layout of equipment. Sentence for them to take act by saying. After working with thousands of customers in since 1943 we’re familiar with the questions that most people have when considering purchasing concrete block and mixing machinery systems. So I’ve tried to answer in as concise language as possible the 75 most common questions that you should be asking yourself before purchasing industrial paving stone and block making machines. Simply click on “The Only Block Machine Buyers Guide You’ll Ever Need“.

If you have questions, please e-mail me at billfleming@globalmachinemarket.com or pick up the phone and call my office at 314-960-0540.