Concrete Batching & Mixing Owners:

“Overwhelmed what size cement, fly ash, lime, coal, bottom ash or aggregate silo will make your operation the most efficient”?

Fly Ash & Cement Storage Silos with automatic weighing

Don’t make the mistake of designing a system where the silo plant is waiting too long to batch cement or other materials. It will cost you money and delay your production.

If you don’t size the silo properly it will cost you money and lost profits for years by slowing down your operation. There are many considerations such as height, diameter size and total capacity requirements. Ready to know which silo type is best for the operation and maximize profits?

Want to know which type cement or fly ash silo is best for your operation?

Custom built aggregate storage silos for weigh batch system

Global Machine Market is the industry leader in custom built design silos designed specifically to fit your needs. We specialize in providing an integrated storage tank system, prescribing the right storage tank design tailored for your requirements and the unique qualities of the material stored.

We welcome the opportunity to help you grow your business by offering equipment and systems to many parts of the world. We also supply silos to many industries in the market which may include one you are in listed below?

INDUSTRIES

- Concrete building block industry

- Concrete prestressed industry

- Cement and aggregate bagging industry

- Concrete Interlocking Paving Stone industry

- Concrete Precast industry

There is an endless amount of different materials we have built silos for material storage but the most common are list below. If you have a material not listed, please give me a call at 314-960-0540 and we can discuss your needs for storage and determine the flow rates need for your application.

MATERIALS

- Cement Fly Ash

- Lime

- Coal

- Color Pigments

- Bottom Ash

- Aggregates

- Frac Sand

To be of assistance to our customers and Global also provides the following services:

- Unlimited phone support answering your questions and consulting services.

- Silo static load specifications and foundation drawings included at no charge.

- Prompt storage silo tank quotations including turnkey installation

- Auxiliary equipment to coordinate silos with other equipment systems.

- Service technicians for equipment installation and training.

- Material testing services through an independent consultant

- Parts and service on silo tank parts, retrofits, field repair and maintenance.

We remedy the producer’s storage problems of the past by prescribing the correct variables of hopper slope, outlet size, outlet configurations, materials of construction and surface finish, active flow-aid devices, passive flow-aid devices, applicable codes and the correct flow type required for reliable material flow.

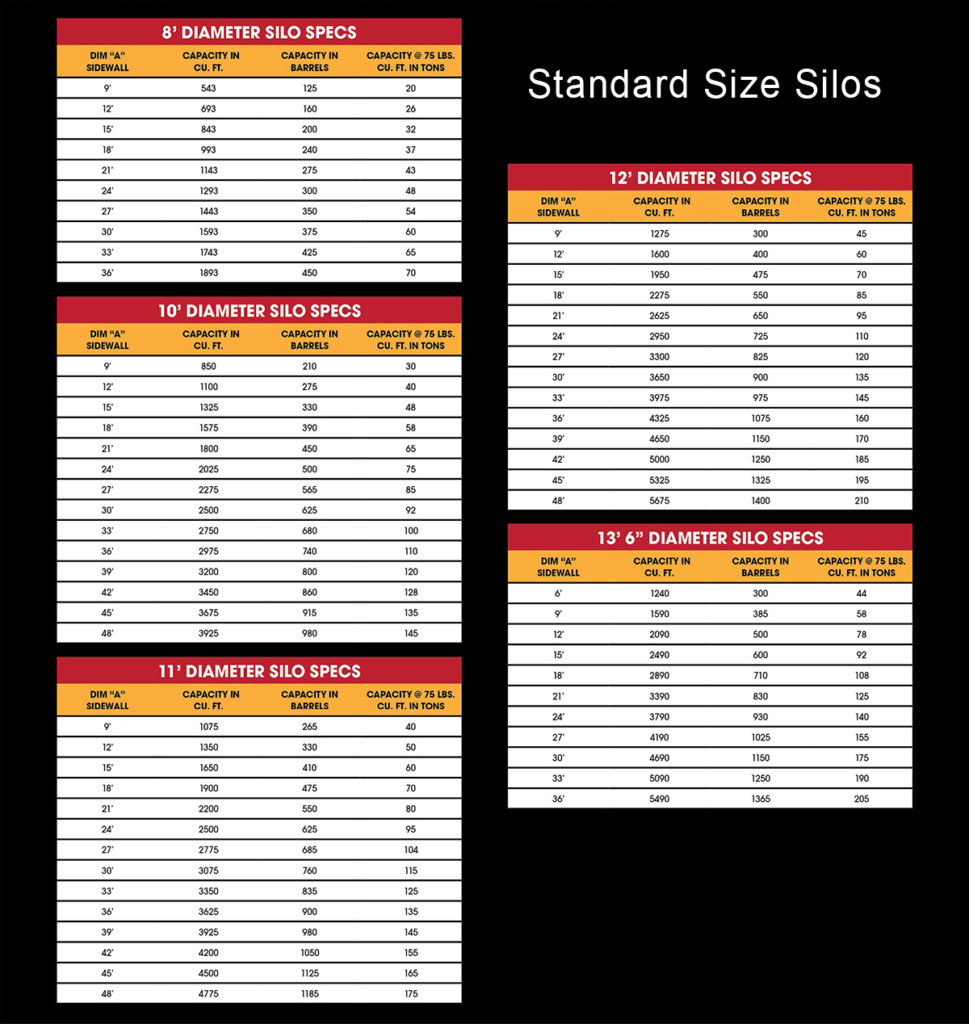

I can offer you a complete one stop experience by supplying you the silo and addition equipment engineered to fit your facility. If you are needing a complete custom plant built with aggregates bins, weigh belts systems, concrete mixer and total plc control automation you need to pick up the phone or email me today to further discuss you plant design. Listed below are the specifications and capacities regarding to our standard size silos. If you don’t see the size you are needing or have additional questions, please give me a call at 314-960-0540 to learn more and I look forward to talking with you.

Standard Silos are equipped with the following.

Standard Equipment: Legs with 3′ – 6″ clearance under discharge, jam gate, outside ladder with cage – full railing, 4″ blower pipe with aluminum. Adapter, 150 sq. ft. dust house with air vibrator and pop off valve manhole, 8 externally mounted air pads with manifold, sand blast, prime, and paint standard color (white, light grey, dunes tan, cat yellow).

White Cement & Grey Cement Silos feeding automatic batching

Portable Cement & Fly Ash Silos.

Portable low-profile cement / fly ash silos are a unique way to go to the job site and be a secondary source of cement storage long side feeding a portable concrete batch plant. The cement silo also has the advantage of generally not requires not requiring any permitting on sites. We offer portable cement and fly ash silos in many silos sizes. They range from (200 Barrel) 800 cu. ft. and are legal 8’-6” wide x 13’-6” tall with legal 26’ overall length for the unit shown below.

Larger portable cement and fly ash cement silos are available upon request up to (300 Barrel) 1200 cu ft.

Call 913-766-125 and ask for more information today.

Portable Cement Silos are offered from (200 Barrel / 800 cu. ft.) – (350 Barrel / 1200 cu. ft.) and legal to tow without permits.