Global Machine has as a heritage of three generations in the concrete industry building concrete machinery and supplying support equipment that is essential to make the systems work properly. Production pallets, or if we were in the bakery business (Cookie sheets) are what the building blocks are formed on, The production pallets then are normally placed in racks and placed in curing rooms for overnight curing.

Good quality products pallets are essential to the quality of making good concrete products and the efficiency of a concrete products plant operation. Purchasing production pallets can often be the most under rated yet important component of any new or existing block and paving stone plant.

There are various materials that production board are made such as steel, wood, or plastic. They each fit a certain block and paving stone machine application best depending on your specific product needs. Some of the common but not all the questions to help choice which type pallet is best for you can be very simple questions.

- Does your product line require steam curing?

- Will you be palletizing the products manually, semi of with fully automatically?

- Will you be putting production pallets into racks?

- What will be your budget?

- What is the weight of the products you are producing?

- How critical is the height control of your product?

- Does your palletizing handling system clamp and lift the product off the product pallet?

- Does your palletizing handling system push the products off the pallet?

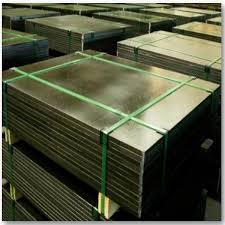

STEEL PALLETS

Steel pallets are by far the most common pallet used with block and paving stone machines in the USA and fast becoming the preferred pallet in the world. This is because it enhances the performance of the block machine with uniform vibration transmission in the molding process ensuring faster and better compression. In addition the wear resistant and durability against concrete abrasion and ability to handling heavy weights of products is very good. The steel pallet also has few side effects issues from being in an atmospherically controlled curing chamber environment compared to other material types of production pallets.

When purchasing any type of pallet, and especially steel is absolutely vital to make sure they are flat, dimensionally square, have deburred edges, and radius corners. If the pallets are not made correctly it will cost you downtime because the pallet with not will not effectively flow through the block machine and handling systems. This can possibly cause damage to production pallets, racks and even your equipment. The other major reason pallets need to be flat is so you make good concrete products! Poor quality pallets affect the quality of your concrete products triggering premature cracking, soft spots and height control irregularity in your concrete products.

That is one of several reasons we never recommend or will supply you a steel pallet that have been made from any coil rolled steel. I have one case study in the industry where a new individual was coming into the industry. He literally thought it was a great idea to save a fifty cents on each production pallet and have the local ship yard with no experience. His thought process was a production pallet is just a plate of steel. How hard can that be to make. I will have it made locally by a nearby shipyard, even though they had never made a production pallet previously.

He had placed the order with the ship yard 3000 pallets and they had to scrap return the entire order. It ended up costing him a loss in just the pallet cost $105,000.00 not including the loss of production time and bad products made. All this money lost to save fifty cents a pallet and because the steel pallets warped and edges would jam the pallet feeding systems in the block machine and rack loader unloader systems. Then when he would make a block the mold would raise and the production pallet would spring back to its original coil rolled shape cracking his products. He did not even have the production pallets three months and was already see the steel starting to rust and flack apart.

You will never have that issue we us because you will only be supplied with flat plate steel in the process of making your steel production pallet.

Your steel pallets and racks can be designed to your exact specifications. You will be supplied a production pallet that has undergone a two-step past treat flattening process to ensure the pallet production board is flat within 1/16” tolerance. Whether it is a steel pallet or steel building block products racks you can be supplied with either metric or imperial measurements. The steel pallets are made to your specifications. Standard thicknesses are available from 3/16″ to 5/8″ or in metric sizes.