| Item | Description |

| 2333 | Hess Egg Layer Type Machine. Hess BF standard SF (1996) Hardly run, exit 4 molds: flower pot, concrete retaining wall, step stacker, curb with corners and bumper stops. |

| 2398 | Fleming Patio King slab casting machine 24×36 capacity includes 18 Fleming molds 800 production pallets. |

| 1298 | Rimac Impacta Turntable slab machine. Complete with 5 sets of various slab moulds. |

| 1156 | Hess HSII-A (1990): pan mixer, molds, 540 production pallets, mobile batch plant (2002), call for details. |

| 1065 | Hess HP3 (1981): multi-layer, production pallets, 6 molds. |

| 2365 | Fleming MF-3 (1985) with upgraded controls/stacker and production pallets and molds. |

| 2167 | Rino Duplomatic Slab Machine. Reconditioned in 1991 and has spare parts and slab molds. |

| 2011 | CMS Model 36 wet cast slab making machine. 28” x 32” mould capacity with 4000 ABS bluestone moulds and carriers. |

| 1365 | Fleming Patio King 24 x 36 (1980) including 18 patio molds 1400 production pallets. |

| 2985 | Zenith 840 (1984) paver stone machine: has hard face unit, several molds. |

| 2390 | Fleming MF-3 concrete block machine (1985) 24 x 36. Upgraded controls/stacker and production pallets and molds. |

| 1111 | Rino Duplomatic Slab Machine (1979). Single station tamper head concrete compaction. |

| 2666 | Tiger TG-4 block and paver stone machine, (1998) with automatic mold change, racks available with used molds. spare parts, 2,000 pallets. |

| 1003 | Hess HT-250 Hydromat (1984) paving stone machine: Stored in warehouse and only used for one year. Concrete machine is in good condition. |

| 2318 | Fleming MF-3 24” x 30” (1998) concrete paving stone machine with controller, stacker and production pallets and molds. |

| 1994 | Tiger PS100 paving stone machine with face mix, complete concrete plant. Approx 4400 steel plates. 10 molds first in first out Tiger handling system, cuber, etc |

| 1490 | Hess Multimat RH 1000-2 concrete paving stone machine.(1997). Can still be seen in operation. Concrete block machine only for sale. |

| 2509 | Fleming Eagle (1992) paving and patio stone machine: 39″ x 52″, 200 gallon hydraulic tank, PLC controls, completely refurbished in 2006; Fleming auto stacker (1992) with hydraulic unit and controls. |

| 2333 | Hess HP III A Multi layer paving stone machine. Has updated controls and PLC. |

| 1222 | AME-FBH-1200 Egg layer block machine. (1999) Capacity size is 1250 x 1100mm. |

| 1996 | Reid Fleming Eagle Excel ( 2004) 40×48 pallet machine and automatic Fleming stacker. |

| 1915 | Reid Fleming MF-4 block and paving stone machine. 24”x36” capacity 2004 model. Includes ten rampf paving stone molds. |

| 2902 | Tiger TG-3 building. automatic mold change, clamp cuber, racks, 2800 pallets spare parts. |

| 3478 | KVM Type 60/105 building block paver machine. (1997) 750 x 1400 pallet size. Complete with automation and twenty kobra moulds. |

| 3234 | Omag (1990) Tronic concrete block machine, elevator OMAG 7 stages, Finger Car Rekers, Omag Lowerator, pallet feeding device dry side, hydraulic product pushing unit, cubing unit Omag, transport pallet magazine, pallet brush, pallet turning device, pallet cube magazine. Omag ZM1000 mixer, silo with up forwarding belt, 3-chambers silo approx 1900 pallets. |

| 2221 | HESS RH 2000 A concrete paving stone and block machine. – one machine silo, complete with hydraulics and PLC-electric control, pallet size 1400 x 1100 mm. Pallet handling system incl. elevator, lowerator, Rekers finger car 9 stages, 2 pallets / stage, stage distance 440 mm, product turning device, cuber with 4-sides-clamp, pallet turning device, pallet stacking device, cross- transportation – as pallet magazine, Transportation pallet magazine with chain conveyor, Product-carrying-away – slat conveyor 28 m long, strapping device Sander horizontal with plastics, complete PLC-electric control for pallet handling system. Approx. 2.500 pallets, different Hess moulds for blocks, hollow blocks, |

I have observed in my career, people and companies that are considering purchasing used paving stone equipment do the research for one or three reasons. The first reason is they are wanting to replace existing equipment at an affordable price. The second reason is they buyer needs an affordable solution for a new venture or expansion to grow their business. Lastly the buyers budget cannot afford new concrete paver machinery and is forced to purchase used equipment. In any of the three categories they have one common trait that will always remain the same for any business that purchases concrete machinery. It is vital in understand prior to purchasing concrete paving stone equipment you have the experienced people that have the knowledge and understanding in how to operate, maintain, or rebuild used equipment. This will greatly increase your opportunities for success in your business.

I have seen countless occasions when buyers financially trap themselves because they don’t have qualified people trained to understand concrete machinery. Buying on just low price only in the concrete machinery world can lead you into a disaster if you do not understand this industry. In the concrete interlocking paving stone machine industry, unlike many other industries you rarely just press the “GO” button and watch the machinery operate. Well trained people are what make the difference in concrete machinery operating or sitting ideal not making you money. Used Hess, Zenith, Besser, Columbia equipment can operate with great performance with well-trained operators. In fact, with good people the age of machinery can mean very little difference in overall performance. This is because of the strength and long last qualities of the machinery in this industry. It is not uncommon to see twenty and thirty-year-old equipment being put back into operation and having very good performance. However, if you neglect to invest in good people your investment will be wasted.

Depending on your delivery time requirements, budget and skill of labor, I offer three levels of equipment choices you can purchase equipment. The different levels can make producers money in several ways. Many business owners often tell me that even with skilled employed workers, the company can often make more money by having the equipment reconditioned or renovated away from their factory. This is because the employees may be working to many hours now and don’t have any additional time available for projects. The concrete interlocking paver producers plant may also not have the physical space or the proper tools in their facility to do such a task. The worker can make the company more money for the company operating and managing their existing facility than spending time on rebuilding their own equipment.

One of my most successful customers told me as we walked through his plant a statement I we never forget. “We do what we do best and that is make concrete products, and that is what makes us money. I want my people to focus making quality concrete products at top levels of production efficiency. Nothing else. That is what makes us the most money possible!

Are you ready to find the level your company needs to be, and what it will take to grow your facility to the next level? Below are the levels of equipment conditioning you can purchase individually or as complete plant set ups from me. If you have any questions, please Contact Bill Fleming.

Level I – Totally Reconditioned Interlocking Paving Stone Machines

Level II – Used in good working order Interlocking Paving Stone Machines

Level III – Sold as Is Interlocking Paving Stone Machines

Are you ready to get started?

I can help you in your journey of finding the right concrete block and low maintenance Interlocking Paving Stone Machines within your budget that meets all your needs. There are just two simple steps to get started:

- The first step is to Contact Bill Fleming, and tell me which level Interlocking Paving Stone Machine equipment package seems to be the right fit and tell me more about your background and any questions you have about the level you are choosing.

- You can also just pick up the phone and call me, so we can discuss the possibilities over the phone. Just dial 314-960-0540. Global Machine Market is located in the Central Standard Time Zone of the USA.

Level I – Totally Reconditioned

The machinery is shipped in from the field or from your existing factory to the rebuilding facility. The machinery is completely dissembled down to the raw frame of the machine, sand blasted. All new component parts, electrical components and new PLC control systems are installed. Any new equipment upgrades are included in the price of the machinery. The machinery is painted, fully tested, certified, looks and operates like brand new Interlocking Paving Stone Machine equipment, and is packaged ready for shipment.

Besser V312 Reconditioned Block Making machine.

This level of reconditioned level 1 equipment packages is often purchased by users that are already in the concrete business and are upgrading their existing concrete products Interlocking Paving Stone plant facility. Generally, the pricing is 50% to 65% the price of new machinery compared if you were to purchase new from the original high priced German manufacturer. In some cases, the machinery is exactly the same equipment including the control systems. Why would any block producer want to buy a new piece of machinery when they could buy reconditioned machinery with factory warranty at a fraction of the cost and still gain the same output production?

What is unique about working with Global Machine from Anyone else?

Our level 1 machine systems have been widely installed and operated internationally in over 80 countries in the world. High growth countries such as the below are very popular destinations for the concrete machinery. In recent years these include Haiti, Bahamas, Jamaica, Dominican Republic, Nigeria, Ghana, Ethiopia, Angola, Cameroon, Guyana, Liberia and many most countries in Africa.

When a person is considering the purchase of a machine system from us I always try to explain to them the benefits and unique differences of working with us over anyone in the world market. I hope these reasons will help you to better understand my company and provide valuable information to help in your journey of choosing our equipment for your needs. If you might be challenged and confused about block machinery systems on the market today there are many major differences. Have suppliers been telling you they make the best machine? They will guarantee the best price in the world? The block industry is simple or just buy our machine and get started today and I can ship to you, no problem? We please read the below and I think you will find the honest answers you are looking to have.

Global Machine Market is a USA company and is real and reputable. My grandfather Harry Fleming family started making concrete machinery in 1943. Three generations later you can pick up the phone and talk to Bill Fleming the owner of the company.

1. Level 1 machines are rebuilt and normally always USA machinery made in North America.

2. Machinery makes concrete products that can exceed ASTM standards in high quality required in the USA.

3. Heavy built machinery that uses less wear parts than most competitive machines built from other parts of the world.

4. Profession Installation men are available to install, assist and train your staff at your location. If anyone tells you their block machine is so simple you don’t need startup training and all you need is their training video they are either nuts or lying to you. All block machinery takes training requires how to install, operate and maintain no matter how big or small of system. The difference with us is we will tell you the truth and make sure you know the challenges in advance so you do have any unforeseen surprises. In doing this you will be saving a lot of money and have machinery you can operate for decades.

5. We help you design a fully profitable interlocking paving stone and retaining wall production plant operation and help you with the design and offer suggestions in how to layout the equipment to work the best fit your land space or building.

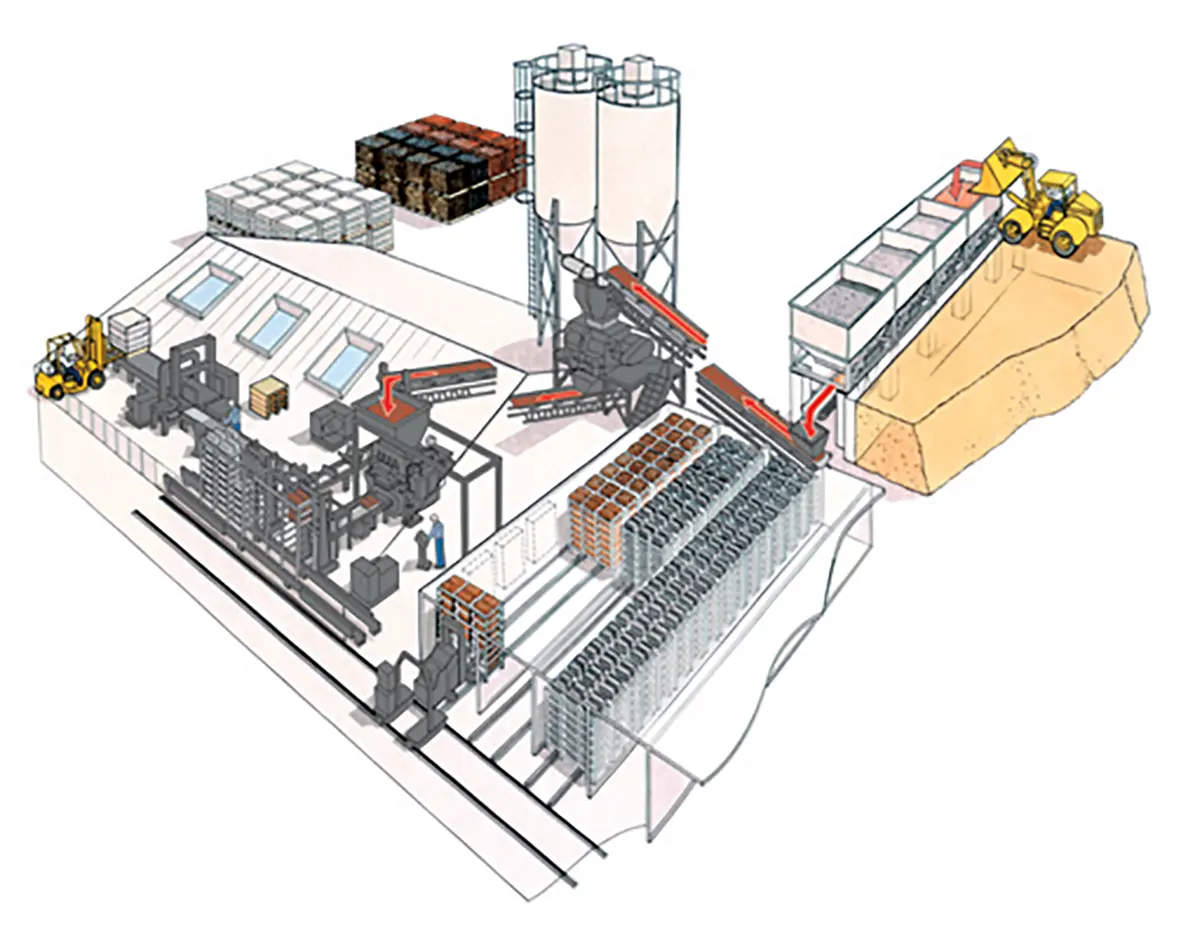

Plant layout for automatic paving stone or block plant

Plant layout for automatic paving stone or block plant

6. Unlimited consulting benefit program to help grow your business. After you purchase your machinery we offer a free consulting program where you can talk to directly with Bill Fleming the president of the company on any issues to help grow your business.

7. Personalized mix design, analysis, testing and formulations are available using your sand and rock aggregates before your machinery arrives.

8. Your first concrete products will be saleable and up to USA high quality standards, saving you time, money and reputation in the market.

9. We will help you understand the type and qualities of production people that are needed to operate and maintain this type of plant. This can save you time and a huge amount of money by getting these types of people. The cost of making bad products, having poor production efficiency and expensive production headaches can be prevented by using us in this step.

10. Our people are fluent in English and Spanish. This is important when you need to talk to us for any service questions, parts and future equipment questions in the future.

11. Optional pre-training in the North America factory and visits to operating block making factories before your machine is shipped. This is to ensure your operators have hands on training in all aspects of a block making business. This will include learning how to make concrete products, daily operational plant procedures, operational maintenance procedures and much more. On the same trip you can have the benefit of being training on the actual machine company you purchased. You will be able to inspect the machinery prior to shipment and meet the full staff of people that will be working with you in the future. The goal is to back home to your site and already be 80% pre-trained before your machine arrives at your site. This will save and make you more money than anything I can recommend for you to save money and ensure your business success before the service technician arrives.

12. You will know in advance of signing any purchase agreement the total cost of the machinery. Included in that total we will also see the service and installation cost and shipment cost landed to the shipping port of your choice.

13. Depending on your weather conditions, availability to local parts and distance from any access to cities or airports in the world we will put together a customized recommended spare parts list for one year’s running operation of the machinery

Level II – Used in good working order

The machinery is disassembled and shipped back to rebuilding facility where the equipment is reworked and supplied in good used working condition. Any obvious parts that need to be repaired or replaced are done to make machinery fully operational. Equipment is fully tested, steam cleaned, repainted and ready for shipment. No upgrades are made to the machinery or no new electrical controls are added to the machinery.

We can discuss on a case by case basis based regarding the equipment and state and explain that mechanical upgrades and electrical controls that may be available. These items will have to be discussed in detail and priced once the equipment is in the rebuilding shop. Once the machinery is being inspected we will know the exact condition of the equipment and advice you the best solution.

Used in good working order Besser Dynapac block making machine

The advantage for you as the buyer is the security and easy of mind to come in and inspect the equipment prior to shipment. You will know the equipment functions and machinery works well because the concrete machinery will be dry cycled before your eyes and before being is dismantled for shipment.

Level III – Sold as Is

The machinery is supplied and sold to you located from its original location and client is responsible for machinery condition. Sold as is, means you are totally responsible for the current condition of the machinery with no guarantees of performance or operating condition. What you see is in pictures or on your personal sight visit is what you are purchasing.

Columbia Model 1600 Sold as is condition

Generally, I only recommend people and users that are currently in the concrete industry purchase Level 3 as is equipment unless they have the very knowledgeable people to service and understand the challenges of used equipment discussed. When concrete machinery is sold “As Is” the equipment is rarely in the condition you can just start operating unless some rebuilding is done to the equipment.

However, the nice advantage of this level choice is you can actually schedule in advance to go inspect the equipment with us and see in person what you will be purchasing. I always recommended to inspect equipment in person to limit any confusion and know exactly what you are purchasing.

Compared to purchasing new overpriced European Interlocking Paving Stone Machines and equipment deliveries can be a matter of weeks instead of many months. International customs duties can also be extremely low compared to new equipment cost.

The savings can be tremendous if you find the right equipment, at the right time. Some situations can be highly advantage to consider with very little risk.

I can help you get a total turnkey solution, including installation, by supplying an operation that is up and operating utilizing either all new equipment, or a combination of new, used and renovated equipment to fit you budget and time frame. The end result is a complete operating plant that is up and operating economically and to capacity.

Please review the materials give me a call at 314-960-0540 or click on Contact Bill Fleming.

I cordially invite you to call me so we might be able to set up plant tours of equipment in operation similar to what you are considering if not the exact machinery itself. We can also layout plant options for your operation. Look forward to hearing from you as soon as possible. Have a great week.

To Your Success,

Bill Fleming

Global Machine Market

Overland Park, Kansas, 66212 USA

Office: 314-960-0540

Cell: 314-960-0540

Skype: GlobalMachineMarket