Level 1 (Advanced Professional) is the most serious level of concrete wet cast slab and veneer stone products production. Companies are driving to produce the highest product output, using the least amount of labor with the end result of making a superior quality product, at a high profit and low unit cost. The operating plant layout designs normally incorporate all new highly engineered concrete equipment and the building is designed around the manufacturing equipment for operational inefficiencies.

Level 1 Production Systems Produce a wide variety of Veneer Stone colors and shapes.

Normally companies or individuals have been in concrete wet cast slab and veneer stone business for many years either manufacturing, buying or reselling products before purchasing this level of equipment package. If the producer has not previously been in the concrete wet cast slab and veneer stone industry it is vital to the success of the company to have a strong sales and marketing team. The volume of products that this high production wet cast slab and veneer stone machine line generates requires a good sales team for distribution.

Fully Automatic Wet Cast Slab or Veneer Stone plants can be operated with few as two people.

This type of concrete producer is normally very strong in marketing and equally skilled in having totally automated manufacturing systems, processes and procedures at all levels. All aspects of the concrete batching, mixing, concrete wet cast slab and veneer stone production handling system and palletizing processes are fully automatic. Click on the following link to view a concrete wet cast slab making plant operation in action https://www.screencast.com/t/LVRqx4yV

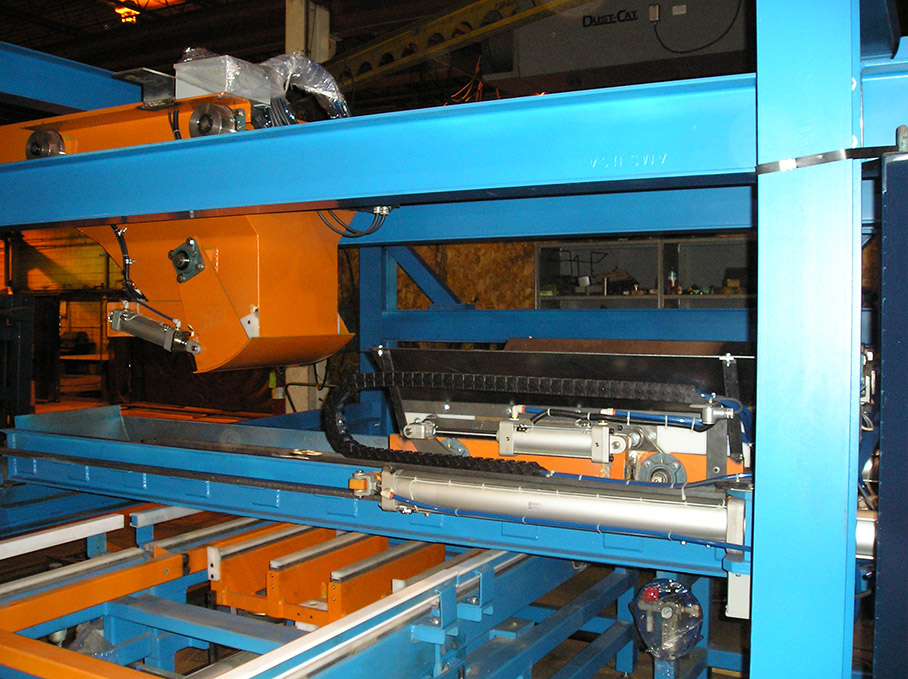

Using advanced robotic palletizing slab system and fully automatic handling and curing system all the produce to utilize the least amount and increased consistency in product quality standards.

Wet Cast Doser for wet cast Slab or Veneer Stone Molds. Once molds are filled concrete mix they are vibrated and stacked automatically and cured for 12 hours.

A typical production plant would include a batch plant, planetary concrete mixer, cement silo with all the materials being weighed and premeasured prior to being placed into the wet cast machinery. Below are the production outputs a typical plant could expect depending on your specific requirements and production mold carrier size. A typical mold carrier size is 30”x48” (760mm x1220mm) but can vary in dimensions depending on your product specifications and product production requirement. Another option size in 48”x48” (1200mm x 1220mm) A level I high speed dosing machine system can operate to speeds as fast as ten seconds.

Product Production Up to per hour

18″x18″x2″(45x45x4cm) 720 units per hour

Veneer Stone (6 sq.ft.) 1500sq.ft.(139 m2)

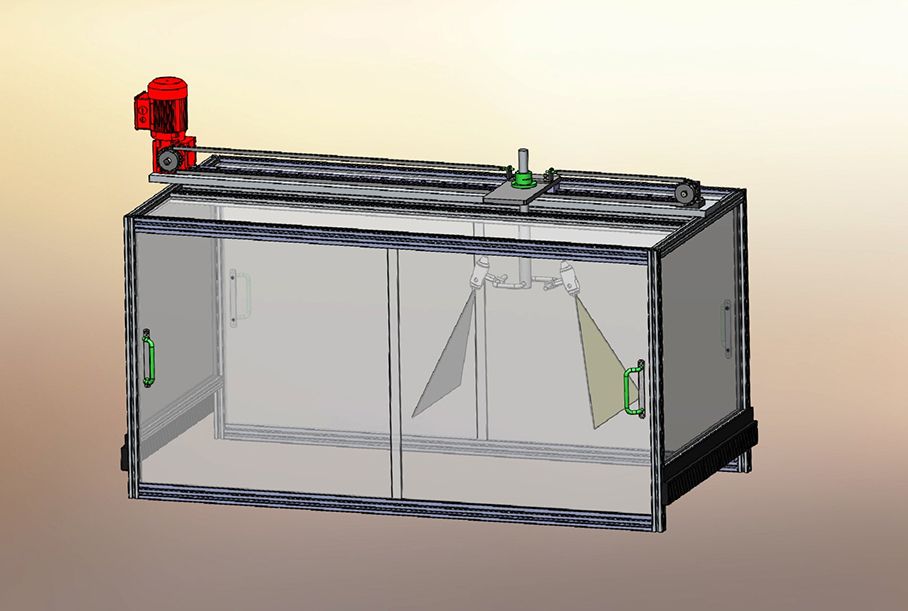

Mold Release Spray Booth for Automatic Application of release oil in wet cast slab or veneer stone molds

When operating a level 1 operation normally the buildings are built specifically to fit around the veneer stone or wet cast slab or cast stone equipment package. However, in many cases we are able to customize the concrete wet cast slab and veneer stone equipment to fit into your existing building if you provide dimensional details. In most cases this level of plant is totally automatic and has no fork lift in the building required for production.

What is unique about working with Global Machine from Anyone else?

Our machine systems have been widely installed in North America many countries. When a person is considering the purchase of a machine system from us I always try to explain to them the benefits and unique differences of working with us over anyone in the world market. I hope these reasons will help you to better understand my company and provide valuable information to help in your journey of choosing our equipment for your needs.

If you might be challenged and confused about the world of wet cast, veneer stone and cast stone machinery systems on the market today, there are many major differences. Some companies might try to confuse you with many statements that confuse people and make them believe the wet cast industry is as simple as buying a car. Have suppliers been telling you they make the best machine? Are promises being made they will guarantee the best price in the world? The wet cast industry is simple or just buy our machine and get started today and I can ship to you, and you will have no problems? Please read the below and I think you will find the honest answers you are looking to have.

Global Machine Market is a USA company and is real and reputable. My grandfather Harry Fleming family started making concrete machinery in 1943. Three generations later you can pick up the phone and talk to Bill Fleming the owner of the company.

- All levels of machinery make concrete products that can exceed ASTM standards in high quality required in the USA.

- We are totally confidential in all conversations about your company and respect your companies trade secrets and ideas.

- Heavy built machinery that uses less wear parts than most competitive machines built from other parts of the world.

- Professional Installation men are available to install, assist and train your staff at your location anywhere in the world. If anyone tells you their wet cast concrete wet cast slab and veneer stone machinery is so simple you don’t need startup training and all you need is their training video, they are either nuts or lying to you. All machinery takes training and requires instructions on how to install, operate and maintain the machinery no matter how big or small of system. The difference working with us is we will tell you the truth and make sure you know the challenges in advance so you will not have any unforeseen surprises. In doing this, you will be saving a lot of money and have machinery you can operate for decades.

- We help you design a fully operational plant and with suggestions in how to layout the equipment to work the best fit your land space or building.

- Free consulting program is free for one year after you purchase your engineered concrete wet cast slab and veneer stone machinery talking directly with Bill Fleming the president of the company. The goal is to help you with advice in any way to help grow your business.

- Personalized mix design, analysis, testing and formulations are available using your sand and rock aggregates before your machinery arrives. Your first concrete products made will be saleable and up to USA high quality standards, saving you time, money and reputation in your market.

- We will help you understand the type and qualities of production people that are needed to operate and maintain this type of plant. This can save you time and a huge amount of money by getting the correct talent of people. The cost of making bad products, having poor production efficiency and expensive production headaches can be prevented by using us in this step.

- Our people are here to help and guide you through the journey of setting up a concrete wet cast slab and veneer stone plant operation. This is important when you need to talk to us for any service questions, parts and future equipment questions.

- Optional pre-training in the North America factories and visits to plants with operating equipment are available before your machine is shipped on some model of machinery. The wet cast industry, unlike others concrete markets, is with a very confidential market which we must respect, but I do have some customers who are willing to help you depending on your location and equipment package you have purchased.

This will include learning how to make concrete wet cast slab and veneer stone concrete products, daily operational plant procedures, operational maintenance procedures and much more. On the same trip you can have the benefit of being trained on the actual machine system your company has purchased. You will be able to inspect the machinery prior to shipment and meet the full staff of people that will be working with you in the future.

The goal is to send you back home to your site and already be 80% pre-trained before your machinery arrives at your site. This will save you start up time and make you more money than you can believe before starting production. Doing this in advance will help increase the opportunities for your business success before the service technician arrives.

- I also have available to you several sources of concrete wet cast slab and veneer stone productions molds. For an additional fee, I have available a one-day class that will teach you all the techniques that are required in learning how to manufacture the correct concrete and color wet cast slab and veneer stone products. You will also receive a certificate of certification in veneer stone production, quality control and technical processes after taking the class.

- You will know in advance of signing any purchase agreement the total cost of the concrete wet cast slab and veneer stone machines. Included in the offer you will see the service, installation and shipment cost landed to the city or shipping port of your choice.

- Depending on your area weather conditions, availability to local parts suppliers and distance from any access to major cities or airports in the world we will put together a customized and recommended spare parts list for one year’s running operation of the machinery.

- All engineering drawings, plant layouts including electrical specifications are supplied at no charge. Electrical motors will be supplied to your countries Hertz, voltage requirements.

- The electrical motors, controls, PLC software are provided with the best quality and latest technology products available on the market. You will be provided with all the details on units so your local suppliers can supply. In addition, if your staff is already familiar with a particular brand of controls they will be able to understand how to operate the concrete wet cast slab and veneer stone machinery with better education and resources. This will save you more money and time. If you need help with obtaining parts be you become more self-reliant as a company.

If you have more questions about the system, please email me at billfleming@globalmachinemarket.com or feel free to pick up the phone and give me a call at 314-960-0540. You can also search and get answers to many of your common questions by downloading “The only Block Machine Buyers Guide you’ll Ever Need“.