Veteran Producer

In most situations Level 2 producers are currently in the business making concrete products and are looking to grow and expand the company by adding an additional operation. They focus on making concrete products cost effectively.

If they have not been in the manufacturing business prior, they have a grasp on where the sales will come from before opening the operation. Level 2 operations is similar to an average concrete block producer within the USA and are fully automatic to increase productivity and reduce labor cost. All the mixing and batching systems are totally automatic and are monitored by the block machine operator. This level of operation understand systems, procedures, and good preventative maintenance programs are vital to their success in operating a profitable operation using concrete block making machines.

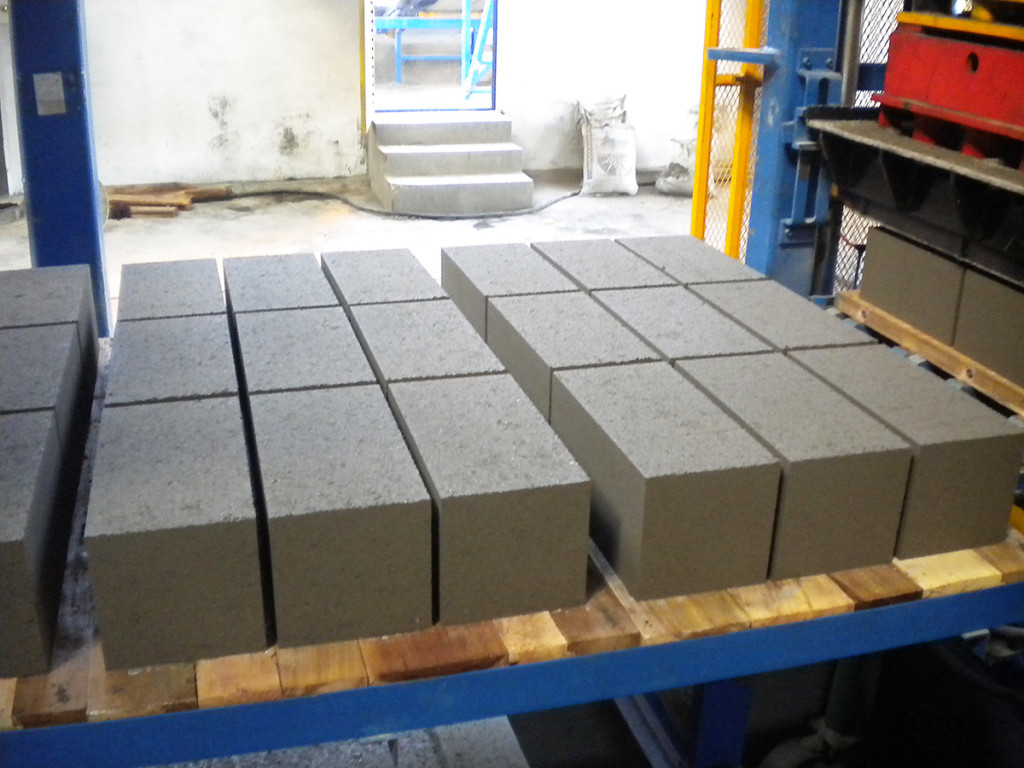

The Level 2 block and paving stone machine is built with an extremely heavy duty frame structure.

One very unique advantage of our machinery is the buyer chooses the preferred brand of operating controls, motors, electric switches that they desire. This is done for two reasons. First, your people might already be trained, comfortable and familiar with a certain brand of controls. Second, you can service and obtain parts locally from suppliers that are closed to your factory. This saves you time and any freight cost instead of coming back to us, even though we have the parts available and can ship to you normally within 24 hours.

The Software includes the most up to date and advanced technology on paving stone machinery in the market today.

Having the ICMS Software system will save you time and money.

#1 Fault diagnosis fault tolerant error correction function module.

Which will greatly help saving time and money trouble shooting any machine operational problems.

#2 Cloud management module.

Whenever you need assistance with your machinery or want to see your plant program when away from the office you will have Cloud access. You can see what is happening with the machinery anytime from anywhere.

Other advantages and features of the new system are incorporated so that the system will allow you to keep your machinery operating and serviced to the top level performance over your competition.

From the technical aspects the level 2 machine is extremely advanced and a technology leader in the market.

- Powerful Variable speed and amplitude Vibrator vibrates mold uni-directionally (vertically), which saves mold wear and produces and denser concrete product.

- Powerful Variable Speed Vibrators allows for adjustable settings and infinite settings for operation of the block making machines operation.

- Level 2 block Machine can be equipped with core pullers or mold insertion device to provide a wider selection of products that can be made on the machinery.

- The simple design and access for service of the machine makes it very easy to maintain and service.

- The machine comes equipped with rotary agitator feed box which allows for faster filling of the concrete into the mold box. This allows you to produce more cycles per day and make more money.

- The machinery can be offered with many different handling systems depending on your budget, building space and products being produced. You can choose from legged pallet systems, Stacker, rack loader/unloader, and finger car systems.

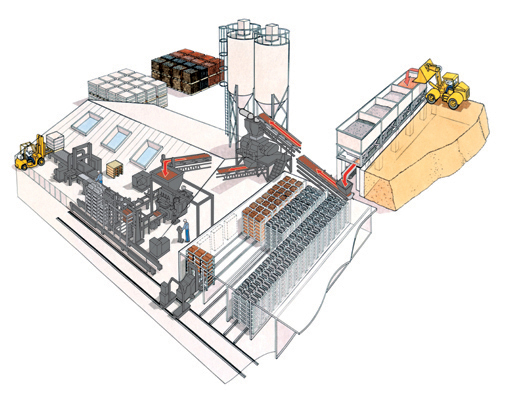

Your concrete block making production plant would include a truck feed batch plant where semi-tracker trailer trucks dump complete loads of aggregates into your aggregate bins. Level 2 batching systems are all automatic to eliminate any labor. The material is conveyed to storage hoppers where the aggregates are ready to be weighed and then conveyor into a concrete mixer. Once proper mixed the material is then sent to the block machine. Below is the production output of a level 2 in an 8 hour production shift.

| Product | Production in 8 Hours |

| 6″x8″x16″(15x20x40cm) | Up to 14,400 Concrete masonry (CMU) units per day |

| 8″x8″x16″(20x20x40cm) | Up to 10,800 Concrete masonry (CMU) units per day |

| Paving Stones | Up to 15,000 sq.ft. (1068 sq. m) per day |

Are you ready to get started making profits and growing your business?

- You need to determine the exact sizes and shapes of products and then e-mail the information to me, Bill Fleming.

- You will need to tell me what country you are planning to install and operate the equipment and when you plan to have the concrete block making machinery producing concrete products.

- You will need to send me information about the amount of land you have allocated to house the operation, along with a sketch or blueprint of the building that the machinery will be located.

- Don’t forget to include the height of the ceiling in the building.

Front end loader block plant operation with automatic Finger Car Operation.

Are you ready to get the answers? If you have any more questions be sure to click on the link of “The Only Block Machine Buyers Guide You’ll Ever Need.” You are always welcome to email me at billfleming@globalmachinemarket.com or just pick up the phone and give me a call at 314-960-0540.