Advanced Professional

The Level 1 building block making machines are very popular for leaders in the concrete industry that want to stay ahead of their competition with technology and performance.

Heavy Built Fully Automatic Block & Paving Stone making Machine. Uses 1400x1100mm (55″ x 43″) pallet size.

Many times labor is expensive and limits the growth of a concrete business in their market area. See if this sounds like you?

- A person already in the concrete business and you are losing orders to the competition because you are not able to produce the products on out dated equipment.

- You have to try to make paving stones on a traditional block machine and can not keep up with the demand and quality issues of your products. You are only making ten pavers per cycle compared to a level 1 machine that make 48 per cycle with less labor.

- Your competitors in the market are making a wider variety of products at lower prices using high production Level 1 paving stone plant machinery. It is vital you look for alternatives or you will not be able to grow your business.

- You are frustrated with the wide variety of products your business is having to produce and your current machinery won’t do the production.

- You are able to make a quality product with your existing machinery but the amount of parts and downtime is eating into your profits and you are not making any money.

- You can’t get parts for your existing machinery because the machinery is very old or the manufacturer is no longer in business. You only have one man in the company that knows how to keep the machinery operating and you don’t want to risk the company’s future on him not showing up one day.

- Your competition makes kerb stones and face mix pavers and you are not able to manufacture them because your machinery does not have the capability. You are now losing jobs that you use to get because they are able to supply a one stop shipping environment for the customer. The customer just wants to go to one producer to by all his products.

- Expanding into new products to grow your business it important and you know only a high production large board paving stone machine will allow you to grow your business

If one of the above sounds like your situation or you just want to explore the opportunities making a lot of money, read below for more information.

Using the same block making machine concrete producers can make interlocking street pavers, face mix pavers, kerb stones, hollow core and solid building blocks all the popular shapes and sizes.

What is unique about working with Global Machine compared to anyone else?

Our machine systems have been widely installed and operated internationally in over 80 countries in the world. High growth countries such as the below are very popular destinations for the machinery. In recent years these include Saudi Arabia, Dubai, Qatar, Algeria and India.

The concept of making interlocking street pavers or other concrete products with dry cast concrete machines it is similar to making cookies. If you would like the entire process explained in detailed and see equipment in action making pavers, please click on the following link. “How it’s Made Pavers” High Production.

You will be impressed with the concept and speed in which concrete products can be made on machinery. All the dry cast paving stone and block machines I offer operate in the same principle as shown. The speeds at which the products are made and level of material automation are the major differences in the machine sizes and plants designs. The quality of the end product is the same whether you choose a small, large, automatic or semi manual operation.

When a person is considering the purchase of a machine system from us, I always try to explain to them the benefits and unique differences of working with us over anyone in the world market. I hope these reasons will help you to better understand my company and provide valuable information to help in your journey of choosing our equipment for your needs. If you might be challenged and confused about block machinery systems on the market today there are many major differences. Have suppliers been telling you they make the best machine? They will guarantee the best price in the world? “The block industry is simple, just buy our machine and get started today and I can ship to you, no problem!” Please read the below and I think you will find the honest answers you are looking to have.

Global Machine Market is a USA company that is real and reputable. My grandfather, Harry Fleming, started making concrete machinery in 1943. Three generations later, you can pick up the phone and talk to Bill Fleming, the owner of the company.

- Our Machinery makes concrete products that can exceed USA ASTM standards of high quality required in the USA.

- Heavy built machinery that uses less wear parts than most competitive machines built from other parts of the world.

- Profession Installation men are available to install, assist and train your staff at your location. If anyone tells you their block machine is so simple you don’t need startup training and all you need is their training video they are either nuts or lying to you. All block machinery takes training, requires how to install, operate and maintain no matter how big or small the system. The difference with us is we will tell you the truth and make sure you know the challenges in advance so you do not have any unforeseen surprises. In doing this you will be saving a lot of money and have machinery you can operate for decades.

- We help you design a fully operation plant and help you with the design and suggestions in how to layout the equipment for the best fit of your land space or building.

- Free consulting program for one year after you purchase the machinery. This includes talking directly with Bill Fleming the president of the company.

- Personalized mix design, analysis, testing and formulations are available using your sand and rock aggregates before your machinery arrives. Your first concrete products will be saleable and up to USA high quality standards, saving you time, money and reputation in the market.

- We will help you understand the type and qualities of production people that are needed to operate and maintain this type of plant. This can save you time and a huge amount of money by getting the right type of people. The cost of making bad products, having poor production efficiency and expensive production headaches can be prevented by using us in this step.

- For international customers we will design and make your machinery to your specifications. You tell us the local electrical brand switches and motors you can obtain locally for quick service and we will install the same brand on your machine.

- Optional pre-training in the North America factory and visits to operating block making factories before your machine is shipped. This is to ensure your operators have hands on training in all aspects of the block making business. This will include learning how to make concrete products, daily operational plant procedures, operational maintenance procedures and much more.

- You will know in advance of signing any purchase agreement, the total cost of the machinery. Included in that total we will also see the service and installation cost and shipment cost landed to the shipping port of your choice.

- Depending on your weather conditions, availability to local parts and distance from any access to cities or airports in the world we will put together a customized recommended spare parts list for one year’s running operation of the machinery.

Level 1 Machines are Built Heavy and Designed for High Production of Products

The Level 1 block, paving stone and product machine is built with an extremely heavy duty frame structure.

One very unique advantage this machinery offers is the Software operating system called ICMS. This system includes the most up to date and advanced technology on block and products machinery in the market today.

#1 Having the ICMS Software system will save you time and make you money by gained production output, advanced service module and much more.

#2 Fault diagnosis fault tolerant error correction function module.

The system will greatly help save time and money in trouble shooting any machine operational issues before any major problem occurs.

#3 Cloud management module.

Whenever you need assistance with your machinery or want to see your plant program when away from the office you will have Cloud internet access. By using your I-phone you can see the operations of the machinery anytime from anywhere. If needed and even make changes to the machinery while the machine is operating from 1000 miles away from the plant facility.

Other advantages and features of the new ICMS system are incorporated which will allow you to keep your machinery operating and serviced to the top level performance over your competition.

From the technical aspects the level 2 machine is extremely advanced and a technology leader in the market.

- Powerful Variable speed and amplitude Vibrator system vibrates mold uni-directionally (vertically), which saves mold wear and produces and denser concrete product.

- Powerful Variable Speed Vibrators allows for adjustable settings and infinite settings for operation of the block making machines operation.

- Level 1 block Machine can be equipped with core pullers or mold insertion device to provide a wider selection of products that can be made on the machinery.

- The simple design and access for service of the machine makes it very easy to maintain and service.

- The machine comes equipped with rotary agitator feed box which allows for faster filling of the concrete into the mold box. This allows you to produce more cycles per day and make more money.

- The machinery can be offered with many different handling systems depending on your budget, building space and products being produced. You can choose from Legged Pallet, Stacker handler, Rack Loader/unloader, and finger car systems.

What are the options available in Level 1 building block machines?

Within Level 1 stationary block machines we have several models to choice from, starting with the largest level output level machine system. All engineering drawings including electrical specifications are supplied at no charge. Electrical motors will be supplied to your countries Hertz, voltage requirements. At your request we can even supply the equipment with your choice of locally available electric motors, sensors and PLC controls. Also, we will supply you drawings for local fabrication of production pallets if you desire to produce the pallets locally instead of purchasing from us directly.

This is the most advanced level of concrete block and paving stone machine equipment systems. Companies that utilize equipment at this level are striving to produce the highest volume output and quality concrete product, highest profit at the lowest cost per unit. Plant layout designs normally incorporate all new concrete block making equipment, and the building is designed around the concrete manufacturing equipment for highest efficiencies.

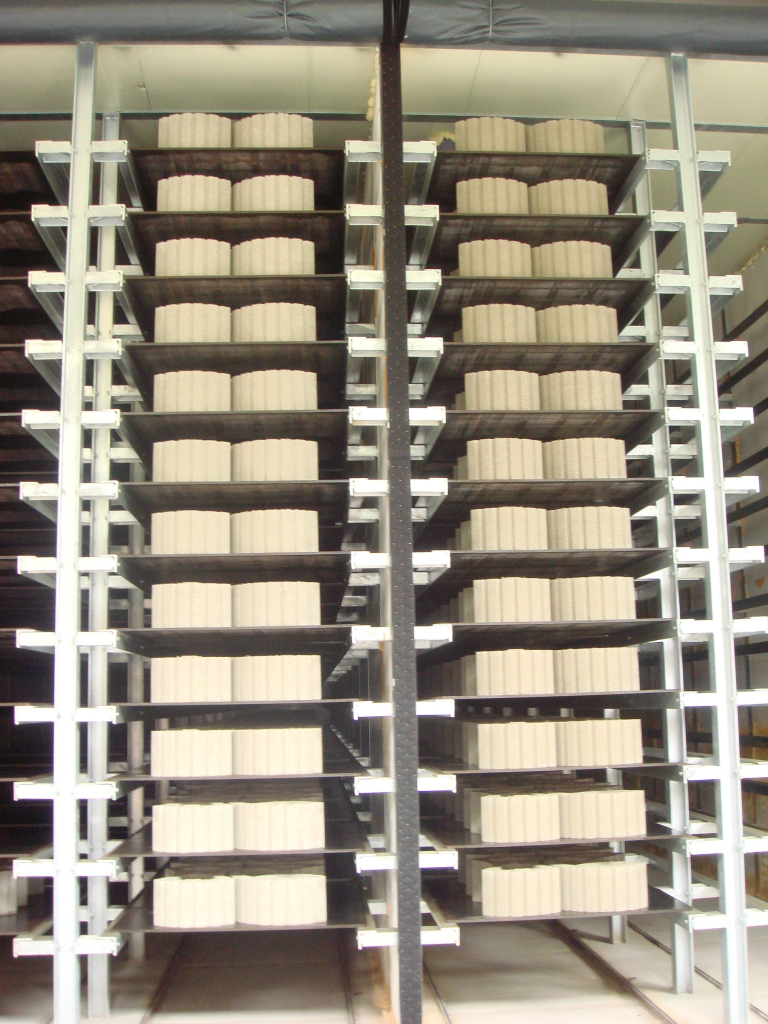

Fully Automatic Finger Car System transports products to & from curing room

Normally, companies that purchase equipment at this level have been in business for many years, however, some new startups do exist given they have the sales demand to justify the high volume of production this system will produce. If the management team has not previously operated a concrete block or paving stone machine in the past it is vital to invest in finding a qualified person to operate and train your people. This type of person needs to be skilled in having previously operated a totally automated manufacturing system and understands processes and procedures at all levels. If you don’t have or cannot find this type of person I can supply extended training options by having our service technicians extends stays at your facility and develop a specific program to fit your needs.

Building Block Machine makes 18 Blocks/cycle with Automatic Stacker System.

A Level 1 system incorporates many individual processing stages and coordinates them together automatically with the end result of making high quality concrete products. These individual operating stages include the concrete batching and mixing of the concrete in preparation for the block machine process. This is where the sand, rock, cement and water are weighed and proportioned into the correct amounts and then dispensed into a blending concrete mixer. Once the materials are mixed the second processing area is the block machine casting and forming of the concrete products. This also includes automatically taking the freshly made units to the curing rooms for overnight storage.

Freshly made Concrete Retaining Wall Units are stored in Curing Chambers for overnight curing

The final processing stage is the packaging line. The concrete products are automatically extracted from the curing room and then placed in position for palletizing. Once the palletizing process has started the concrete products are packaged into the proper shipping cube size and taken to the shipping yard by fork lifts.

The concrete products output production for a Level 1 plant is listed below.

| Product | Production in 8 Hours |

| 6″x8″x16″(15x20x40cm) | Up to 32,000 Concrete masonry units (CMU) per day |

| 8″x8″x16″(20x20x40cm) | Up to 24,000 Concrete masonry units (CMU) per day |

| Paving Stones | Up to 22,000 sq.ft. (2043 M2) per day |

High Strength Building Blocks, Pavers, Landscape products can all be made on one machine

Are you ready to get started making profits and growing your business?

- You will need to determine the exact sizes and shapes of products and then email the information to Bill Fleming at billfleming@globalmachinemarket.com.

- Click onto Buyers Guide and read the descriptive information and then contact me with all your detailed questions.

- Make sure you have dimensional information about the amount of land you have allocated for the block operation. It will also help to send a sketch or blueprint of the building that will house the block making machinery.

- Don’t forget to include the height of the ceiling in the building.

If you need help determining if your building is large enough email your questions to Bill Fleming at billfleming@globalmachinemarket.com or simply call me at 314-960-0540.