(Medium Start-Up Plant)

Producers tend to have a challenge understanding how concrete products are made and need help learning how the entire process of the concrete block machine equipment works together. Although usually entering the market for the first time, producers generally have some contacts in generating sales in advance within the construction industry.

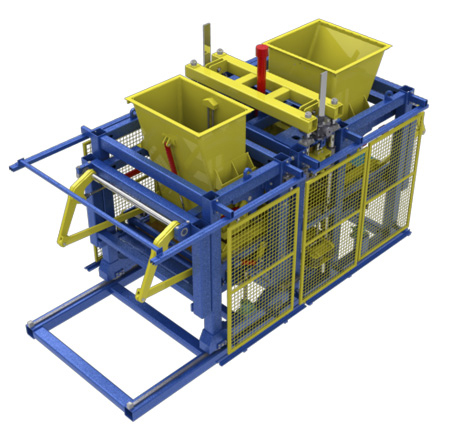

Medium Start-Up Block Plant with mixing, automatic Block Machine and stacking

Therefore, in some cases, they vaguely know the levels of production required for their needs. They often need help understanding the amount of land, cost of concrete block making machines and, electrical supplies required for such a concrete block making operation. If you are considering equipment and need help understanding the business please click on “The only Block Machine Buying Guide You Will Ever need” to help guide you through the process. After you have read the booklet you are always welcome to call me at 314-960-0540.

A level 4 startup plant operation would include a concrete mixer that would be charged with sand, gravel, water and cement using inexpensive labor. I some cases it can include very simplistic batching which stores the aggregates and weighs the materials prior to putting them into the mixer. The concrete block and paving stone machine can make a wide variety of products and can produce the following outputs listed below.

Production Pallet Size of Level 4 Versatile Block Machine is 900 x550mm (35 ½” x 21 ½”) 22 Bricks per cycle.

Level 4 Versatile Block Machine is optional is Face Mix Attachment.

By using a face mix attachment, a producer is able to automatically produce a higher quality textured paving stone with a dense with rich color.

The sustainable benefits are a result of a proven concrete mix formula used in manufacturing which is only super-fine sand granules and granite, one of the world’s hardest rocks combined with cement of the highest quality. This makes the top surface of the paver look esthetically more attractive and durable.

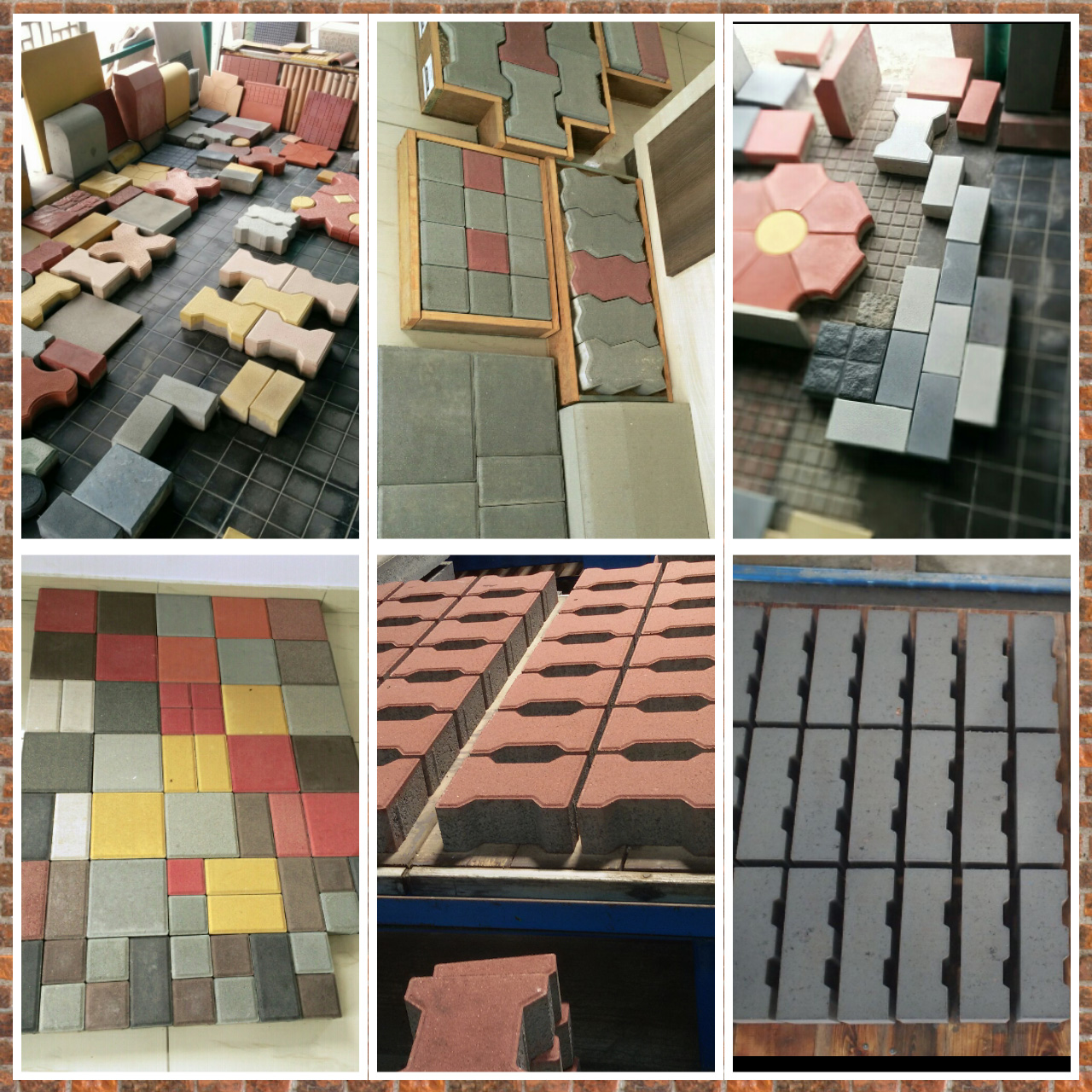

Outputs are listed below of typical concrete products made with a Level 4 block system.

| Products | Production in 8 Hours |

| 6″x8″x16″(15x20x40cm) | Up to 7,000 Concrete masonry units (CMU) per day 1500 |

| 8″x8″x16″(20x20x40cm) | Up to 9,000 Concrete masonry units (CMU) per day 1300 |

| Paving Stones | Up to 4,304 sq. ft. (400 M2) per day |

- You need to determine the exact sizes and shapes of products and then e-mail me the information at contact Bill Fleming. I will contact you within 48 hours and discuss the possibilities to help you.

- You will need to tell me what country you are planning to install and operate the equipment along with any current building requirements the concrete block making machine would need to conform to.

Research the electrical requirements and see if you are able to obtain 3 phase electricity on the site to operate the building block machinery. If you have questions in regard to electrical requirements, please e-mail me at billfleming@globalmachinemarket.com or pick up the phone and call my office at 314-960-0540.